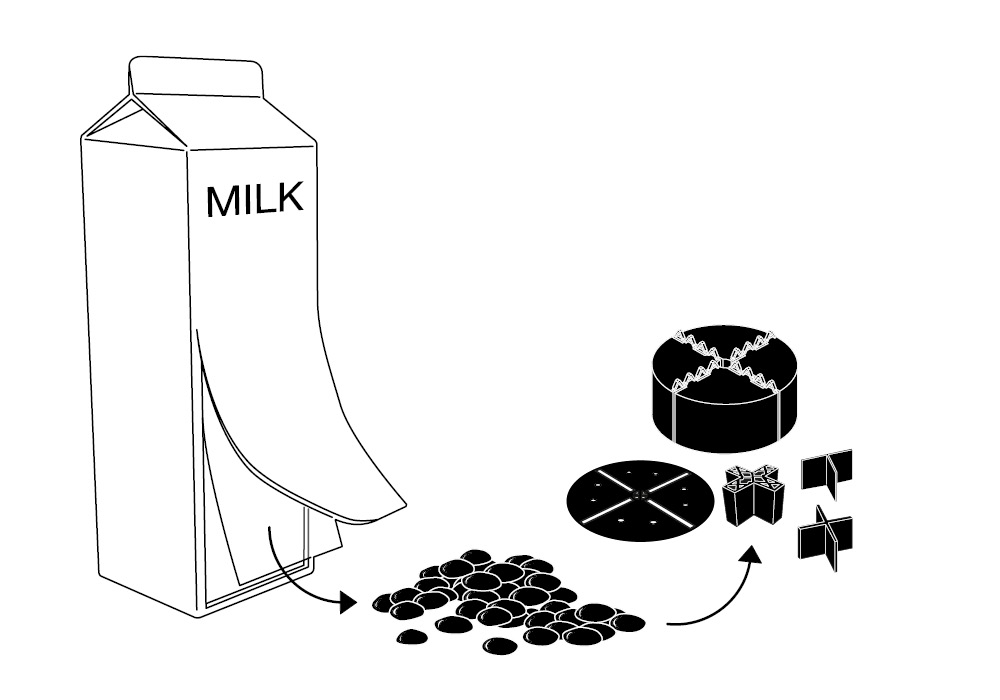

Produced in Denmark with environmentally friendly PE

All PaveSystem products are made from non-toxic Polyethylene (PE). It is the same type of plastic that can be found on the inside of milk cartons.

We manufacture all PE products at our factory in DK-8544 Moerke. Thereby, we have full control over the quality of our products, we ensure safe and healthy work conditions, and use only food-approved, completely non-toxic raw materials and dyes.

PE products are acid-resistant, corrosion-free, and can withstand all types of common cleaning detergents.

Learn more about our materials here.